Glass Bottle Screen Printing

glass bottle screen printing Screen printing polyester mesh is widely used for screen printing, beneficiation, flour, wa

Send your inquiryDESCRIPTION

Basic Info.

| Certification | ISO, CE, SGS |

| Application | Garment, Textile, Graphic, Digital, Glass etc |

| Length | 30m, 50m or at Your Request |

| Mesh Count | 355 Mesh/Inch |

| Width | 0.6m-3.68m |

| Transport Package | Plastic Bags, Carton, Weaving Bags |

| Specification | 140T |

| Trademark | MAISHI |

| Origin | Hebei, Anping |

| HS Code | 5911200090 |

| Production Capacity | 80000 Square Meters/Week |

Product Description

glass bottle screen printing

Screen printing polyester mesh is widely used for screen printing, beneficiation, flour, wastewater treatment, sugar refining, pharmaceuticals, ceramics, food (fruit and vegetable juice pressing), paper,and coal washing industry.Mesh type is available from 6T to 165T (15mesh to 420mesh / inch). Color is available for yellow and white. The widest width can be made upto 3.68m.

------------------ Quick View -----------------------

Micronic mesh for screen printing

1. Material: 100% polyester

2. Type: 6T - 165T

3. Mesh count: 15mesh to 420mesh ( Holes per inch)

4. Width: 0.6m-3.68m

5. Length: standard 30m, 50m, or cut as per your request.

6. Color: Yellow. (White color is also available)

Our mission: Real quality and best price

1. Product introduction

Screen printing polyester mesh is a kind of woven wire mesh which adopts different weaving methods by textile machine. Polyester screen mesh is one of best materials for screen printing, drying and filtration in the world. Polyester mesh has high strength, corrosion resistance, good abrasion resistance, and long life.

2. Normal specifications

| Maishi Monofilament Polyester Screen Printing Mesh (Bolting Cloth) | ||||||

| model | mesh count | APERTURE | THREAD DIAMETER | OPENING | thickness | INK THROUGH VOLUME THEORETICALLY |

| mesh/inch | micron | micron | % | micron | cm 3 /m 2 | |

| 6-400 | 15 | 1300 | 400 | 65 | 780-810 | 560 |

| 10-250 | 25 | 700 | 250 | 49 | 508-518 | 355 |

| 12-250 | 30 | 610 | 250 | 53 | 495-505 | 305 |

| 15-250 | 38 | 467 | 250 | 49 | 489-501 | 213 |

| 18-150 | 45 | 410 | 150 | 53 | 255-275 | 138 |

| 21-150 | 55 | 330 | 150 | 46 | 260-280 | 123 |

| 24-100 | 60 | 316 | 100 | 57 | 136-145 | 109 |

| 24-120 | 60 | 302 | 120 | 51 | 230-240 | 104 |

| 30-120 | 75 | 213 | 120 | 41 | 235-345 | 102 |

| 32-100 | 80 | 212 | 100 | 46 | 145-155 | 69 |

| 36-90 | 90 | 183 | 90 | 44 | 160-165 | 65 |

| 39-55 | 100 | 195 | 55 | 56 | 88-96 | 55.0 |

| 39-80 | 100 | 166 | 80 | 43 | 125-130 | 59.0 |

| 43-80 | 110 | 147 | 80 | 40.8 | 127-132 | 53 |

| 48-70 | 120 | 135 | 70 | 41 | 108-120 | 45.5 |

| 54-55 | 135 | 118 | 55 | 47 | 88-96 | 44.5 |

| 54-64 | 135 | 115 | 64 | 38.5 | 95-105 | 38.9 |

| 54-70 | 135 | 108 | 70 | 34 | 108-120 | 40 |

| 58-55 | 145 | 118 | 55 | 38 | 89-94 | 39.5 |

| 61-64 | 155 | 105 | 64 | 42 | 98-107 | 33 |

| 64-45 | 160 | 105 | 48 | 43 | 73-82 | 36.5 |

| 64-55 | 160 | 98 | 55 | 38 | 85-95 | 36.1 |

| 64-64 | 160 | 88 | 64 | 30 | 95-105 | 30.7 |

| 68-55 | 175 | 85 | 55 | 34 | 85-90 | 29 |

| 72-48 | 180 | 90 | 48 | 36 | 75-84 | 33.1 |

| 77-55 | 190 | 81 | 55 | 30 | 88-97 | 26.6 |

| 80-45 | 200 | 75 | 45 | 36 | 65-74 | 27.7 |

| 80-48 | 200 | 72 | 48 | 33 | 75-84 | 28.7 |

| 90-48 | 230 | 56 | 48 | 25 | 77-85 | 23.5 |

| 100-40 | 250 | 58 | 40 | 33 | 62-71 | 21.3 |

| 110-40 | 280 | 48 | 40 | 27 | 65-71 | 18.4 |

| 110-34 | 280 | 54 | 34 | 35.5 | 52-57 | 20.2 |

| 120-34 | 305 | 45 | 34 | 30.5 | 52-57 | 18.4 |

| 140-34 | 355 | 31 | 34 | 19.5 | 56-62 | 14.4 |

| 150-31 | 380 | 36 | 31 | 29 | 43-47 | 13.1 |

| 150-34 | 380 | 30 | 34 | 20.5 | 56-62 | 14.9 |

| 165-31 | 420 | 31 | 31 | 23 | 52-58 | 12.88 |

D (DENIER) =MICRON 9D=31MICRON, 12D=34MICRON, 16D=40MICRON, 22D=48MICRON, 30D=55MICRON; 40D=64MICRON, 50D=70MICRON, 60D=80MICRON, 80D=90MICRON, 100D=100MICRON Notice: Other abnormal specification can be produced if the quantity more than 3000sqm | ||||||

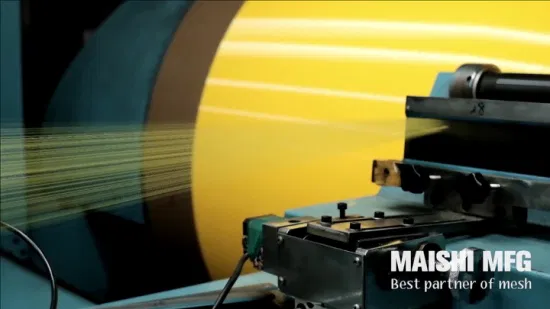

3. Production process

Material yarn from Jintong, Switzerland and Japan, we inspect those yarn arrived (tolerance, tensile strength, physics test etc.).

During production, first we put the warp wires on the beam, drawing the warp wires into heddle and reed. Then our experienced weaver will start weaving mesh according to orders.

Initial survey is taken during and after weaving. Then the heat setting treatment and physical properties inspection will be done before we get tentative finished rolls (normally 60-500 meters rolls).

In the end, after the final inspection, we will cut the mesh into small rolls (20m-50m) according to customer orders.

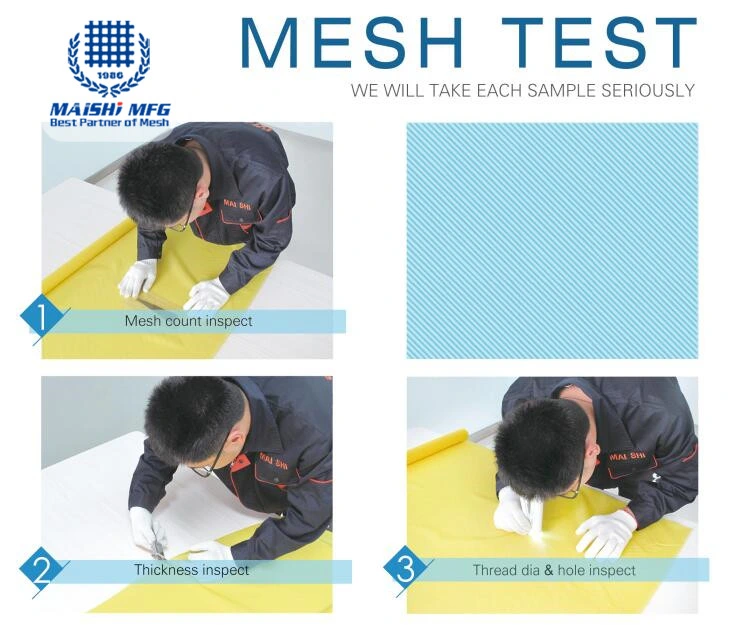

4. Mesh Test

MAISHI test printing mesh before the goods dispatched from our factory to ensure their quality.Make sure customers get perfect quality.

Testing include:

1> Mesh count inspect

2> Thickness inspect

3> Thread dia & hole inspect

4> Elongation test

5> Tensile test

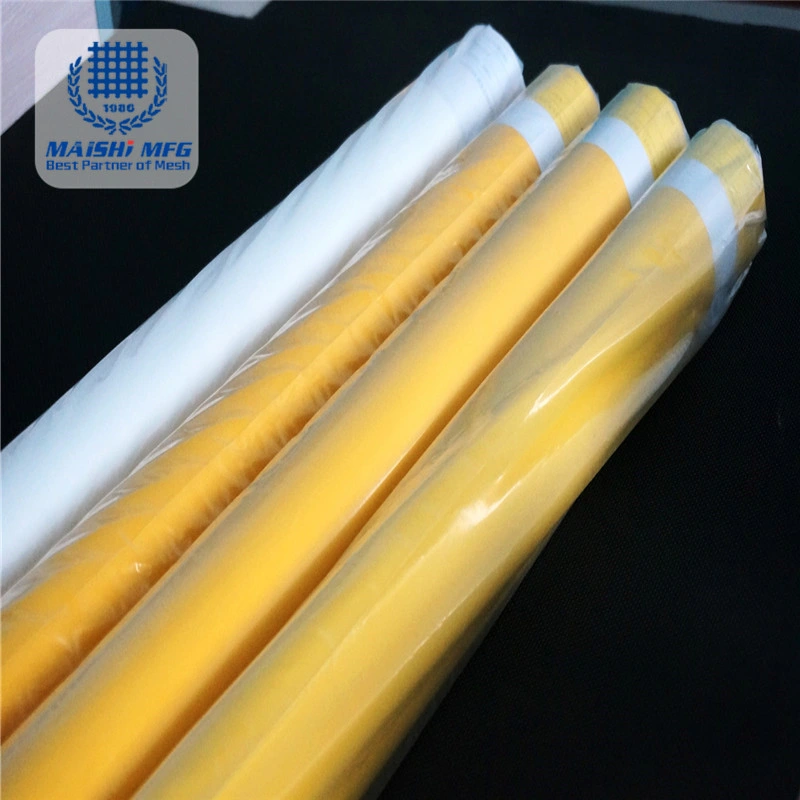

5. Packing

We have two kind of packing type:

1.Fold the mesh into plastic bag ,then in carton.Suitable for small quantity and have no requirement on the crease.

2.Pack the mesh with paper and plastic bag,then in carton.Suitable for large quantity and the mesh has better surface then folding type.

Folding packing

Rolling packing

Paper carton package

Outside pack with weater-proof weaving cloth

6. Application

1> Ceramic printing / Glaze printing

2> Garment Printing

3> Glass printing

4> PCB printing

And other applications include:

CD/DVD Printing,

Ceramic Decorating,

Graphic Screen Printing (Glass Containers, Labels,Large Format UV Graphic, Small Format UV Graphic, Solvent Graphics, Tubes and Cartridges),

Package Printing,

Printed Electronics,

Printing on Glass,

Solar Cell Printing,

Textile Printing,

Tableware.

Any need for Screen printing polyester mesh, please contact us and let us know your specifications, include:

1. Material

2. Mesh count

3. Wire diameter or hole size

4. Mesh color

5. Roll size

6. If you can tell your application, it will be much helpful

7. Quantity

Maishi is always here for you!

Related Products